Faucets in such facilities need to be in constant operation and have to be very durable as they have to be clean as well. Airports have thousands of passengers daily, and colleges have many students where restrooms are utilized by a massive number of people; health care facilities involve many staff members and also an immense number of visitors on a daily basis. Knowledge about the basic parts of a faucet will help minimize the time they are off and also increase safety features for the users.

This article is clear enough in describing every internal component and its functionality, failure and what the facility managers can do to prolong the life of the system and help lower its maintenance costs.

Cartridges: The Core of the Faucet

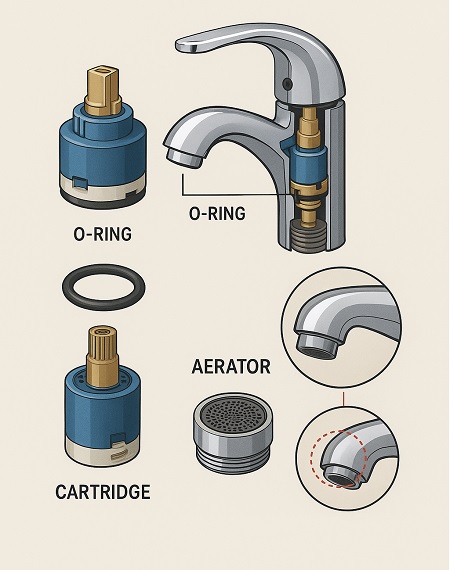

A faucet’s cartridge is essentially the heart of the water control mechanism. It regulates water flow, mixing, and shutoff accuracy.

Types of Cartridges

- Ceramic Disc Cartridges – Most common today; extremely durable and reliable.

- Compression Cartridges – Older style, more prone to leaks; still found in older buildings.

- Thermostatic Cartridges – Maintain stable temperature, essential in hospitals and some airports.

How a Cartridge Works

The cartridge controls how hot and cold water mix as the handle is moved. In touchless faucets, a solenoid initiates flow, but still the cartridge modulates pressure and temperature.

Common Cartridge Failure Points

- Wear of ceramic surfaces → Causes dripping even in OFF position.

- Mineral buildup → Leads to stiff handle movement or inconsistent flow.

- Erosion from high-pressure systems → Seen in airports and older campus buildings.

- Faulty thermostatic element → Dangerous for hospitals because incorrect temperature increases scalding risk.

Why This Matters in High-Traffic Facilities

- Hospitals: Temperature accuracy is highly crucial for patient safety. A malfunctioning cartridge could breach safety guidelines.

- Airports:Cartridges face heavy cycles a day—durability is an important factor.

- Colleges: Students often misuse handles; robust cartridges reduces expensive repairs.

O-Rings: Small Components with Big Impact

Humanized Text:

O-rings are gasks that are made of rubber to avoid leakages at the handle, base of the spout and the joints of connection.They are cheap and yet important.

How O-Rings Function

The O-rings act by expanding and contracting in response to a change in water pressure to seal the water. They are also conducive to ease in rotation of handles.

Common O-Ring Failures

- Hardening and cracking due to age or heat.

- Chemical degradation — In particular, in hospitals that apply stronger disinfectants.

- Incorrect lubrication — rubber can be spoiled by use of low-quality grease.

- Water chlorination — accelerates drying and cracking.

- Wrong-size replacements — a common issue in college maintenance teams.

Symptoms of Failing O-Rings

- Leaks around the base of the spout

- Side drips during handle movement

- Mold or moisture buildup on counters

- Reduced handle mobility

Why This Matters

- Hospitals: Liquid intrusion encourages bacteria growth; sealing integrity is essential.

- Airports: Large washrooms multiply water loss costs due to dripping of dozens of faucets.

- Colleges: Leaking faucets raise water bills for campus facilities that are already operating on a tighter budgets.

Aerators: The Hidden Tool for Efficiency and Hygiene

The aerator is the net assembly at the faucet’s tip. It helps in mixing the air with water to minimize the fluid flow while maintaining pressure at the same time.

Functions of Aerators

- Control flow rate

- Reduce water waste

- Improve user comfort by reducing splash

- Filter out small debris

- Maintain laminar or aerated flow

Types of Aerators

- Standard Aerators – Used in public washrooms with 1.5 GPM flow.

- Laminar Flow Devices – Necessary for hospitals to reduce airborne bacteria.

- Vandal-Resistant Aerators – Common in airports and college dormitories.

Common Aerator Failures

- Clogging from mineral scale → Causes weak flow or uneven spray.

- Bacterial contamination in hospitals → Requires frequent flushing or replacement.

- Damage from vandalism – Common in crowded public environments.

- Improper flow specifications – Replacing with wrong GPM may violate efficiency standards.

Why This Matters

- Airports: Aerator obstructions leads to long wait times and poor passenger experience.

- Hospitals: Wrong aerators compromise infection control.

- Colleges: Obstructed aerators usually lead students to misuse faucets, causing most wear.

Common Failure Points in High-Traffic Environments

Failures often occur for predictable reasons. Understanding of such reasons help the maintenance teams to act before costly breakdowns take place in future.

Mineral Scale Buildup

- Airports in humid climates and colleges in hard-water regions see rapid scaling.

- Solenoid valves and aerators clog quickly.

Wear from High User Volume

- Handles and cartridges exceed their designed cycle count.

- O-rings flatten faster under constant motion.

Incorrect Maintenance Procedures

- Using petroleum grease on O-rings

- Over-tightening aerators

- Installing off-brand cartridges that don’t fit perfectly

Water Pressure Surges

- Pressure spikes damage cartridges and seals.

- Hospitals especially rely on pressure-stable systems for patient washing stations.

Chemical Exposure

- Disinfectants used in hospitals can degrade rubber seals more quickly.

- Airports that use strong cleaners in high-traffic tourist restrooms face similar issues.

Maintenance Strategies for Airports, Hospitals, and Colleges

Airports

- Use vandal-proof aerators and high-durability cartridges.

- Keep mineral flush schedules every 2–3 months.

- Stock spare solenoids and cartridges for peak footfall times.

Hospitals

- Prefer laminar flow devices instead of aerators in clinical zones.

- Replace O-rings and seals quarterly due to chemical exposure.

- Use of a certified thermostatic cartridges for the prevention of any potential scald risks.

Colleges

- Standardize faucet models across various buildings to ease the repairing process.

- Use tamper-resistant aerators in dorms.

- Train future student maintenance interns for detection of early sings of leakage symptoms.

Preventive Maintenance Checklist (Quarterly)

- Inspect all faucets for any leakage around the spouts and handles.

- Eliminate and thoroughly clean aerators using vinegar or a descaling solution.

- Exchange worn out O-rings and apply a silicone-based lubricant.

- Inspect cartridges for stiffness or inaccurate temperature control.

- For touchless faucets, test the solenoid function and replace weak or low charged batteries.

- Log each service action to identify repeat problem fixtures.

Conclusion

The functionality of faucets has a direct impact on hygiene, conservation of water, and functionality in areas such as airports, hospitals, and colleges. The crucial components of the faucet include cartridges, O rings, and aerators. If the building managers were able to understand the functionality of these components and what may cause their failure, it is likely that they will be able to plan smarter maintenance.

In order for organizations to extend the life span of their faucets and also reduce water waste, they should invest in quality parts and maintain them accordingly.

References

- American Society of Plumbing Engineers. (2024). Plumbing engineering design handbook (2024 ed.). ASPE. https://aspe.org/pipeline/2024-version-of-aspes-plumbing-engineering-design-handbook-volume-4-is-now-available/

- U.S. Environmental Protection Agency. (n.d.). High-efficiency faucet standards (WaterSense product specifications). EPA WaterSense. https://www.epa.gov/watersense/product-specifications

- World Health Organization. (2023). Water, sanitation and hygiene in healthcare facilities (2023 data update). WHO. https://www.who.int/publications/m/item/wash-in-health-care-facilities-2023-data-update

- Sloan. (2024). Solenoid and sensor maintenance guides [Technical manuals]. Sloan. https://www.sloan.com/resources/technical-documents

- T&S Brass and Bronze Works. (2024). Cartridge and aerator specifications [Product literature]. T&S Brass. https://www.tsbrass.com/resources/literature/product-literature

- NSF International. (2023). NSF/ANSI/CAN 61: Drinking water system components – Health effects. NSF International. https://standards.nsf.org/discussion/nsfansican-61-2023-drinking-water-system-components-health-effects-uploaded