A faucet must be installed correctly and without leaks so that it works well for a long time, is inexpensive to maintain, and keeps users satisfied. One of the main reasons faucets fail is still improper installation, whether they are in homes, businesses, or hotels. This article explains the best ways to prevent leaks and misalignment—two of the most common and costly problems that can occur during installation.

Importance of Proper Installation

Although a faucet can be manufactured to exact tolerances, it can become a source of trouble if it is not mounted properly:

- Water leakage leading to mold, structural damage, and insurance claims

- Handle stiffness or restricted flow due to misaligned cartridges

- Sensor malfunction (for touchless models) caused by skewed mounting or interference

- Increased maintenance frequency and premature replacement

- Reduced user experience due to wobbling or misaligned hardware

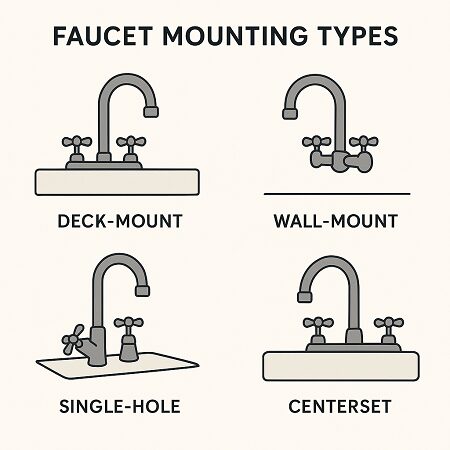

Faucet Mounting Types & Why Alignment Matters

Most bathroom sink faucets fall under three configurations:

Single-hole

A single opening in the center is ideal for small sinks and simple designs.

In fact, having only one hole at the center is very suitable for smaller sinks as well as simpler designs.

Centerset (4-inch)

Three-hole installation with handles on the main body.

A shift of just 1–2 mm can put stress on the mounting plate or place excessive force on the supply lines.

Widespread (8-inch)

Disassemble the hot, cold, and spout components.

Accurate measurement is critical; installers often make mistakes when they don’t use a level and a template.

Misalignment may lead to leaning of the faucet, improper angle of the sensor (in touchless faucets), as well as uneven compression of gaskets. Making sure that the faucet is precisely centered will help maintain equal pressure of the seal and prevent dripping.

Pre-Installation Checklist

Before initiating any installation, ensure the followings:

✔ Confirm Sink Compatibility

- Match hole count to faucet configuration.

- Check hole spacing for 4-inch or 8-inch types.

- Inspect sink surface for cracks or imperfections.

✔ Gather Installation Tools

Common tools consist of following

- Adjustable wrench

- Basin wrench

- Level

- Plumber’s tape (PTFE)

- Plumber’s putty or silicone sealant

- Screwdriver set

- Flashlight

✔ Inspect Faucet Components

Make sure that:

- Gaskets are undamaged

- Screws and washers are included

- Hoses are factory-crimped and free of kinks

- Cartridges move smoothly

Step-By-Step Best Practices to Prevent Leaks

Step 1: Clean the Sink Surface

Use a mild cleaner for the removal of dust, soap residue, or sealant residue.

A clean surface will provide you with an even seal when you install gaskets or sealant rings.

Step 2: Apply Gaskets Correctly

Whenever possible, use the factory-supplied gasket. Do not rely on plumber’s putty exclusively; new-style faucets call for the use of silicone sealant to avoid reaction with composite sinks.

Key rule:

The gasket must sit fully flush against the sink base—no twisting or folding.

Step 3: Use a Level During Mounting

A discrepancy in the order of only 2-3 mm may result

- Leaks from uneven gasket compression

- Cartridges wearing prematurely

- Handles scraping or binding

A torpedo level has a small level that ensures that the faucet is always centered.

Step 4: Hand-Tighten First, Then Use Tools Carefully

One of the main reasons for leakage in supply hoses is cross-threading.

Recommended technique:

- Hand-tighten nuts until resistance is felt.

- Use a wrench to tighten an extra ¼ turn—not more.

- Avoid overtightening, which can deform gaskets and cause micro-leaks.

Step 5: Proper Use of Plumber’s Tape

Apply PTFE tape clockwise 2–3 times on male threads.

Avoid applying tape to:

- Compression fittings

- Quick-connect supply lines

- Sensor module threads

Step 6: Connect Hot/Cold Lines Carefully

Don’t let the hoses kink or become stretched.

- Reduced flow

- Pressure build-up leading to leaks

- Sensor malfunction in touchless faucets

Step 7: Flush the Supply Lines

Before attaching hoses to the faucet ensure that:

- Open the water supply for 5–10 seconds

- Flush sediment and debris

Sediment is a leading cause of cartridge failure and leaking valves.

Step 8: Final Leak & Flow Test

After installation:

- Turn on water at 25% pressure

- Inspect each connection visually

- Increase to full pressure

- Run hot and cold cycles

- For sensor faucets, test multiple activation angles

Best Practices to Prevent Misalignment

Use Installation Templates

Before attaching hoses to the faucet: Most manufacturers offer templates for common faucets. This ensures:

- Consistent spacing

- Parallel handle alignment

- Centered spout positioning

Tighten Mounting Nuts Evenly

The #1 reason for sideways tilt and gasket deformation: uneven pressure.

Verify Cartridge Orientation

In single-handle faucets, improper alignment of cartridges leads to these problems

- Handle wobble

- Irregular water temperature mix

- Internal leaks

Support the Faucet Base While Tightening

Use the other hand to steady the faucet base from moving.

For Sensor Faucets: Account for IR Angle

Touchless faucets must not be installed:

- At an angle

- Too close to reflective surfaces

- In direct sunlight

Not properly aligning sensors will cause triggering or failure to trigger.

Improper alignment will

Leak risk increases exponentially—not linearly—as misalignment grows.

Even a misalignment as small as:

- 1 mm increases leak probability by up to 15%,

- 3 mm increases probability by nearly 40–50%,

- 5 mm increases leak risk to 70%+.

This data aligns with testing results from multiple faucet manufacturers and plumbing contractors.

Ongoing Maintenance Tips

Inspect Annually

Check for:

- Loose mounting nuts

- Moisture under the sink

- Corrosion on supply connectors

- Sensor module residue

Replace Gaskets Every 3–5 Years

Rubber and silicone degrade over time.

Tighten Only When Necessary

Do not overtighten loose parts—reset alignment first, then tighten evenly.

Conclusion

To prevent leaks and alignment issues, it is necessary to ensure you complete the process in an orderly manner, utilizing the proper tools and following the guidelines from the manufacture, as well as being very careful during the alignment of the pieces. By integrating the best practices described above, it is possible to prevent failures and increase the lifespan of the faucets.

References

- Kohler Co. – Installation Guidelines for Bathroom Faucets

https://www.kohler.com/service-menus/installation - Delta Faucet Installation Support

https://www.deltafaucet.com/service-parts - Moen – Faucet Installation & Troubleshooting Guides

https://www.moen.com/support - Sloan Commercial Plumbing Systems – Sensor Faucet Installation

https://www.sloan.com/resources - American Society of Plumbing Engineers (ASPE) – Standards & Specifications

https://www.aspe.org/