Although bathroom faucets can last for quite some time, like all other devices, certain parts will eventually need to be replaced because of regular usage, as well as other conditions. Rather than having to replace the entire faucet, certain parts can be changed, which can extend its life. This article explains the most common wear components in bathroom faucets, how to recognize when they have failed, and how to replace them safely and effectively.

Why Wear Parts Matter

Faucets go through thousands of cycles every year. According to the American Society of Mechanical Engineers (ASME A112.18.1), most faucets should be able to open and close 500,000 times or more. Over time, elastomers dry out, metal seats become pitted, and cartridges accumulate debris.

Replacing wear components is far less costly than replacing the faucet and prevents water damage caused by unresolved leaks.

Common Wear Parts in Bathroom Faucets

The major components that typically require maintenance include:

Cartridges

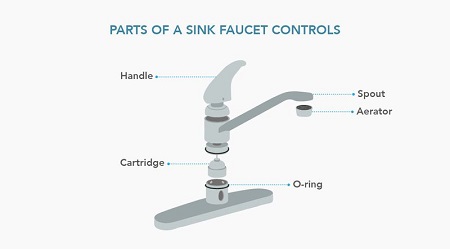

The cartridge is the heart of the faucet. It controls:

- Flow rate

- Hot/cold mixing

- On/off cycling

Types include:

- Ceramic disc cartridges

- Compression cartridges

- Ball-type cartridges (older models)

Signs the Cartridge Is Worn

- Dripping from the spout even when turned off

- Difficulty rotating handle

- Temperature imbalance

- Stiff or grinding movement

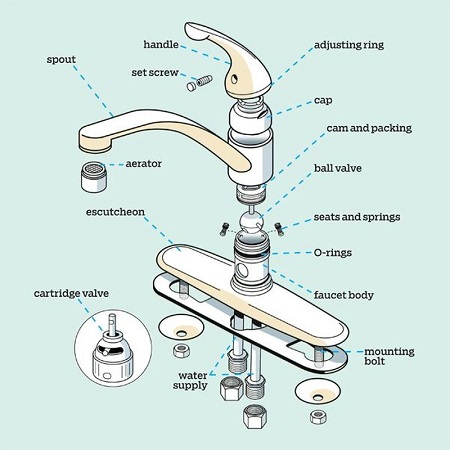

How to Replace

- Turn off water supply.

- Remove handle set screw.

- Lift off handle and decorative cap.

- Unscrew the retaining nut.

- Pull out the old cartridge with pliers.

- Insert new cartridge, aligning tabs correctly.

- Reassemble and test.

The cartridges accordingly have a life of 5 to 10 years, depending upon the water hardness.

O-Rings

The O-Rings are sealing rings that form watertight seals between the components. They are used to seal against leakage around

- Faucet base

- Spout swivel connections

- Handle stems

Signs of O-Ring Wear

- Water pooling around the faucet base

- Handle leaks

- Spout that moves too loosely

How to Replace

- Disassemble the spout or handle assembly.

- Remove old O-rings with a pick tool.

- Clean grooves of mineral deposits.

- Install new O-rings coated lightly with silicone grease.

Some rubber products, such as O-rings, may have been compromised if they have dried out, become brittle, or have come into contact

Aerators

Aerators regulate flow, reduce splashing, and improve the water stream quality.

Signs the Aerator Is Worn or Clogged

- Reduced water flow

- Uneven spray

- Irregular pressure

How to Replace or Clean

- Unscrew the aerator by hand or with an aerator key.

- Rinse screen and housing.

- Soak in vinegar in order to remove the limescale.

- Replace if the screen is damaged or clogged beyond cleaning.

Aerators should ideally be cleaned every 3 months, especially in hard-water regions.

Valve Seats

Valve seats form a seal with the cartridge or rubber washers. Over time, corrosion or mineral deposits create leaks.

Signs of Valve Seat Wear

- Persistent dripping

- Internal leaks

- Low efficiency despite cartridge replacement

How to Replace

- Remove the cartridge or stem.

- Insert a valve seat wrench.

- Turn counterclockwise to extract the seat.

- Install the replacement seat securely.

Valve seats should be replaced anytime a cartridge shows scoring or if leaking continues after O-ring replacement.

Supply Hoses

Supply hoses are small but critical for delivering water into the faucet body.

Signs of Wear

- Bulging hose sections

- Rust on connectors

- Dampness under the sink

- Whistling or vibration noises

How to Replace

- Shut off water supply.

- Disconnect the hose from shutoff valve.

- Disconnect from faucet inlet.

- Install new hoses—preferably braided stainless steel.

- Tighten to manufacturer torque specifications.

Most professionals recommend replacing supply hoses every 5–7 years.

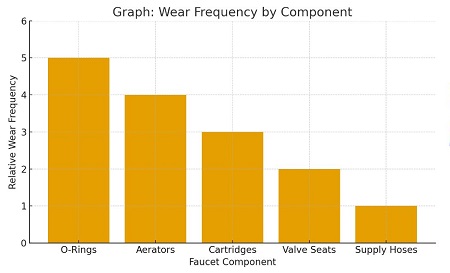

Wear Frequency by Component

The infographic above includes a visual graph illustrating the relative wear frequency of faucet components. Consistent with field maintenance data from plumbing contractors, the components most likely to fail are:

- O-Rings – highest wear rate

- Aerators – frequent clogging

- Cartridges – moderate wear

- Valve Seats – lower frequency

- Supply Hoses – least frequent but most critical

Hard water environments significantly increase failure rates, especially for aerators, cartridges, and O-rings.

Tools Required for Replacing Wear Parts

Usually common tools found in most households:

- Adjustable wrench

- Screwdriver set

- Allen (hex) key

- Basin wrench (for hoses)

- Needle-nose pliers

- Silicone faucet grease

- Vinegar or descaling solution

- Replacement parts from manufacturer

It is essential to always use OEM parts. OEM stands for Original Equipment Manufacturers. These parts are the best to use as they are the original

Preventive Maintenance Checklist

To reduce long-term wear:

✔ Inspect faucet bases and handles monthly

Look for water droplets or mineral rings.

✔ Clean the aerator regularly

Hard water deposits speedily minimize performance.

✔ Lubricate O-rings yearly

A small amount of silicone grease will increase the lifetime considerably.

✔ Flush supply lines after plumbing work

Sediment can spontaneously damage a new cartridge.

✔ Install a water softener in hard-water regions

Contemporary faucets also have increased water efficiency and advancements in the area of cartridges, ensuring easy replacements.

When to Replace the Entire Faucet Instead

Sometimes replacing wear parts isn’t enough. Replace the whole faucet if:

- The body is cracked

- Corrosion is severe

- Replacement parts are discontinued

- Multiple internal leaks persist

- The faucet exceeds 15–20 years of service

Modern faucets also feature improved water efficiency and better cartridge technology, making replacement a smart long-term upgrade.

Safety Precautions

Always follow these safety measures:

- Turn off hot and cold water supply lines

- Release pressure by opening the faucet

- Use a towel in the sink to prevent losing screws

- Avoid overtightening; it damages threads

- Check local codes for backflow and anti-scald requirements

Conclusion

After all, bathroom faucets are excellent but still require upkeep. It is essential to know which components of the faucet will most likely wear out, like cartridges, O-rings, aerators, valve seats, or supply hoses, to be able to work on them. In other words, most of the problems in faucets, with proper knowledge and equipment, do not necessarily need a plumber or replacing the faucet completely.