Introduction

For command-level leaders in hospitals, airports, universities, and other large organizations, plumbing is more than a background utility; it is a critical operational system that influences maintenance budgets, water-conservation goals, facility uptime, and overall user satisfaction. Faucets are among the most common fixtures in any large building. Each Faucet consists of a valve mechanism, and the type of valve will provide different qualities, like reliability, maintenance, consumption, and overall costs.

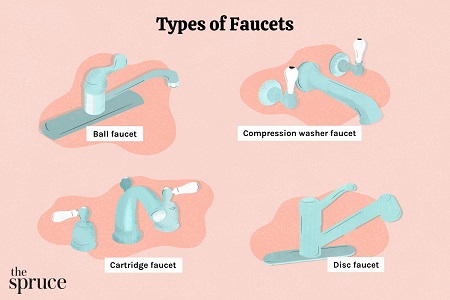

Facility engineers and purchasing managers, as of 2025, will commonly be faced with four basic types of faucet models::

- Compression faucet

- Cartridge faucet

- Ball faucet

- Ceramic disc faucet

This particular article offers a comprehensive, command-level treatment of these types of valves, their operation, and respective implications related to large facility performance.

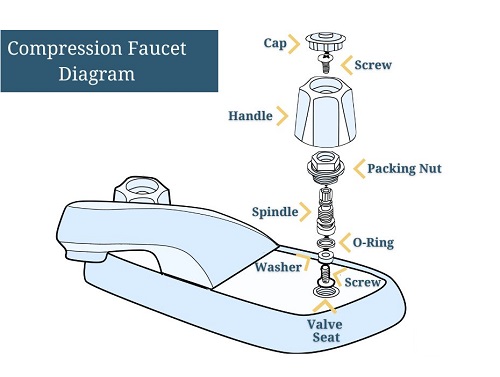

Compression Faucet

How They Work

Compression valves rely on a rubber washer that compresses against a metal valve seat. When the handle is tightened, water flow stops. When loosened, water flows.

Strengths

- Lowest upfront cost

- Very easy to repair

- Parts widely available

Limitations

- High maintenance due to washer wear

- Prone to leaks over time

- Requires multiple handle turns

- Not ideal for high-traffic environments

Organizational Considerations

Compression valves are not recommended for hospitals or airports due to frequent failure points. They are most viable for low-traffic administrative buildings.

Cartridge Faucet

How They Work

A cartridge assembly regulates water flow through linear or rotational movement. It has an internal mixing and flow control system, which is a self-contained system.

Strengths

- Smooth, easy operation

- Fast opening/closing

- Easier maintenance than compression

- More robust for high use

Limitations

- Cartridges differ across manufacturers

- Moderate cost

- Performance degrades if cartridges become clogged with debris

Organizational Considerations

Cartridge valves would be a very strong alternative in universities and in airport applications that aren’t medical because of their balance of cost and durability.

Ball Faucet

How They Work

Ball valves use a rotating metal or plastic ball with a hollow chamber. Moving the single handle aligns the ball’s opening with hot/cold water inlets.

Strengths

- Ideal for single-handle faucets

- Very durable under heavy usage

- Smooth and fast water mixing

Limitations

- Contains many small parts

- Vulnerable to mineral buildup

- Moderate maintenance requirement

Organizational Considerations

Because ball valves are built for rapid, high-frequency operation, they work well in airport restrooms, stadiums, and student unions—places with constant turnover and high user volumes.

Ceramic Disc Faucet

How They Work

Ceramic disc valves use two polished ceramic plates that slide against each other. Because ceramic is extremely hard, these valves maintain a tight seal and resist wear.

Strengths

- Exceptional durability (10–20 years)

- Minimal maintenance

- Highly resistant to temperature and pressure fluctuations

- Best sealing performance

- Fast and precise water control

Limitations

- Highest upfront cost

- Sensitive to debris (requires clean supply lines)

Organizational Considerations

Ceramic disc valves are suited for hospital buildings, luxury airport terminals, or contemporary university buildings with the purpose of maximizing sustainability. Low leakage rates are directly helpful for sustainability objectives.

Graph: Performance Comparison of Faucet Types

The following is a comparative performance chart based on facility engineering standards, manufacturer data, along with plumbing engineering analyses.

Performance Score (1 = Poor, 10 = Excellent)

----------------------------------------------------------------------

Faucet Type | Durability | Maintenance | Water Control | Lifecycle Cost

----------------------------------------------------------------------

Compression | 4 | 3 | 5 | 4

Cartridge | 7 | 6 | 7 | 6

Ball | 8 | 6 | 8 | 7

Ceramic Disc | 10 | 9 | 10 | 9

----------------------------------------------------------------------

Organizational Takeaway:

Ceramic disc valves clearly lead in every major performance category. Although this may be above the price point, operation cost-savings can cover long-term expenses.

Lifecycle and Cost Implications for Large Organizations

Upfront vs. Long-Term Cost

| Faucet Type | Avg. Cost/Unit | Maintenance Frequency | Total Cost Over 10 Years |

|---|---|---|---|

| Compression | Low | High | High |

| Cartridge | Moderate | Moderate | Moderate |

| Ball | Moderate | Low/Moderate | Lower |

| Ceramic Disc | High | Very Low | Lowest |

Water leaks and constant repairs represent real budget drains. Ceramic disc valves reduce failures significantly, especially in settings with continuous usage.

Maintenance Implications

For command-level leaders, staffing and downtime must be considered.

- Hospitals require constant uptime—leaks or malfunctions in clinical areas cannot be tolerated.

- Airports face massive foot traffic; even brief downtime can create sanitation issues.

- Universities must balance tight budgets with thousands of daily users.

The washer in the compression valve has to be replaced periodically in heavy-use applications. The ceramic disk valve does not need maintenance for several years.

Water Conservation Impact

Organizations making sustainability pledges, and more especially ones reporting on LEED, WELL, Green Globes, or ESG metrics, cannot ignore matters of valve selection.

- Compression valves often leak as washers degrade.

- Cartridge and ball valves remain efficient with routine servicing.

- Ceramic disc valves maintain the tightest seal over time, minimizing water loss.

Large hospitals or airports can literally conserve tens of thousands of gallons of fluid each year with the simple elimination of leaks via ceramic disc valves.

User Experience and Accessibility

Valve design influences:

- Ease of use

- ADA compliance

- Temperature stability

- Risk of scalding

Ceramic Disc and ball faucet offer more fluid control and quicker temperature adjustment particularly within healthcare and academic settings.

Recommendations for Command-Level Decision Makers

Hospitals

Choose ceramic disc faucet due to its features of durability, hygienic advantages, and tight shut-off.

Airports

Use ball or ceramic disc faucet to cope with a high number of users and to eliminate interruptions associated with doing the dishes.

Universities & Colleges

Use cartridge faucet for cost efficiency or ceramic disc faucet for more sustainable applications.

Corporate or Government Buildings

Balance cost and longevity with cartridge faucet, upgrading critical areas to ceramic disc.

References

American Society of Plumbing Engineers. (2025). Commercial faucet valve mechanisms: Engineering standards & performance, 2024–2025 [Technical standard]. ASPE.

https://aspe.org/publications-news/aspe-plumbing-engineering-design-handbooks/

Plumbing Manufacturers International. (2025). Valve technology trends in high-use facilities [Industry report]. PMI.

https://www.safeplumbing.org/

U.S. Environmental Protection Agency. (2024). Water efficiency in commercial plumbing systems (WaterSense at Work: Best management practices for commercial and institutional facilities). EPA WaterSense.

https://www.epa.gov/watersense/